The herbal ways of treatment are introduced for ages. People in many parts of the world consider this as the first method of treatment. In many Asian and African countries, it is still the most prominent way of treating the diseases deformities of the people. The reason behind herbal products are still in the market is the non-chemical way of preparing the medicines. It hardly affects one’s health, makes it the better choice for any treatment. Herbal medicine does give slow but long-term results. Hence, the ayurvedic and naturopathy industry is growing fast.

Many people preferably like to take herbal medicines where they alternatives as well. Soon the time will come where the herbal medicines will be in great demand like other medicines. Hence, the count of Manufacturer of Herbal Products has also considerably increased.

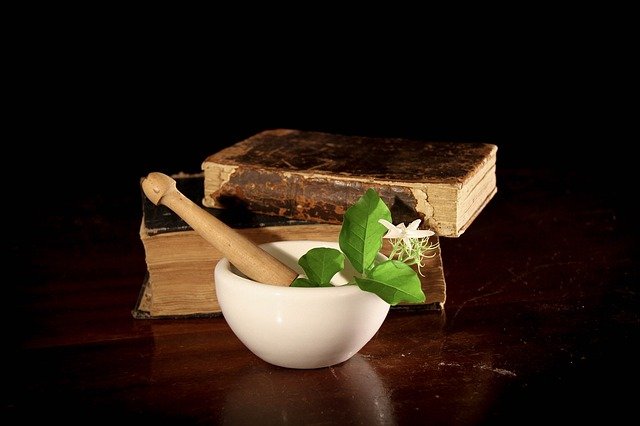

The Manufacturer of Herbal Products processes natural herbs and plants. Out of the plants’ extracts, and juices they make the medicines. The herbal medicines are also called ayurvedic medicines. The Ayurveda is the ancient way of treatment in Indian civilizations. Its effects are long-lasting and undoubtedly have cured some of the fatal diseases as well.

How to be a Manufacturer of Herbal Products?

The process is simple and convenient. One who is going to set up has to have the relevant degree in the field. After that, they have to finalize the products.

Post which, there are certain norms and standards which one on qualifying gets the permission to start the same. These manufacturers of Herbal Products are not only making natural medicines but making the world which may become chemical-free.

To start with anyone can be Juices, processes aloe Vera cream, the herbal tea is in great demand. Setting up the manufacturing of such products does not involve much cost, and one can easily start with limited knowledge.

As a Manufacturer of Herbal Products, the following key points to be kept in mind.

- Check on raw material availability: The raw material supply should be consistent to set the processing industry. It happens with many manufacturers that due to shortage of raw material, their operations were shut. Hence, it is required to maintain the stock of the raw material.

- Storing the right quantity: Storage is another vital point to be considered. While checking the future forecast of the sale, the right size storage or warehouses help in planning the right quantity of manufacturing. The storages should well ventilation for dry kinds of stuff and for preservatives the cold storage facilities are also required.

- Safety: The safety of the raw material and the products manufactured should be taken care of. Hence the safety parameters are many while becoming the manufacturer of Herbal Products.

- Quality check: when it comes to Herbal or ayurvedic products, quality is the utmost benchmark that is to be achieved. One has to make sure before the products are dispatched in the market, the quality check has to be done to maintain the expected quality and continuity of the same product.

- The quality check of raw material: while procuring the raw material, the quality is to be checked as the same product will be processed to the end product.

- Product processing quality: At times, the raw material quality affects the end product. Hence, it has to be evaluated well.

- Post-production quality: The end product should be dually checked before it’s dispatched.

There are varied benchmark standards of the world health organization {WHO}. Manufacturer of Herbal Products has to comply before they do the setup.

By different schemes, the government is also encouraging different start-ups to accelerate the processing and manufacturing of herbal medicines.